Three Sterility-Enhancing Technologies for Aseptic Life-Science Processes

[Author’s Note: This is the first of a three part series of articles on advanced manufacturing technologies for pharmaceuticals.]

Why haven’t the pharmaceutical, biotechnology and compounding industries widely adopted the use of advanced manufacturing technology?

I have worked in the aseptic drug and biologic industry for more than 35 years, and one of the most vexing issues faced daily is the threat of microbial or particulate contamination of the drug or biologic product being filled into its primary packaging. Let’s face it, we have relied far too long on the use of sterile gloves or glove-port gauntlet gloves to prevent the introduction of microbial contaminants into the product to address engineering design flaws in the aseptic isolator or RABS filling systems.

From my observation, sterile surgical gloves, which are typically only 0.19–0.23 mm thick, in most cases do not provide a significant degree of protection for drug products (1). Studies have shown that, besides holes developing in the gloves, they degrade over time when worn repeatedly, generating particles and increasing the potential for holes. Another major issue that the human factor introduces is the potential for contaminating the gloves when donning them. In some cases, poorly trained employees have accounted for greater than 50% of the microbial contamination of gloves found during environmental testing. Even for highly trained employees, there is still a nearly 3% chance of the gloves becoming contaminate. Finally, gauntlet gloves used in RABS and isolators are generally clumsy to use because of their one-size-fits-all approach. I have observed employees manipulating a part or component within an isolator; besides it taking a long time, it requires some contortions to move a component or connect a change part, all the which increases the risk of contamination due to excessive handling.

When you look at glove-port gauntlets for RABS and isolators, holes in the gloves are the number one cause for deviations and investigations conducted for these systems.

Mitigating Contamination

So, to mitigate the potential for gloves and gauntlets to contaminate the products being filled, the industry has adopted extensive personnel and environmental sampling programs, employee qualification programs, leak-testing equipment for gauntlets and extensive use of cascading cleanrooms. This places a significant but necessary burden on industry to ensure asepsis within the manufacturing process.

A better way to increase sterility assurance, however, is by improving current aseptic filling practices. We should eliminate the use of gauntlet gloves in RABS and isolators by designing the filling and stoppering processes using remote manipulators, advanced sensors and robotics to perform aseptic-line cleaning, equipment setup, filling and closure operations.

I recently had the opportunity to tour a BMW automobile assembly plant, and I was astonished by the significant use of robotics in the assembly of their vehicles. While discussing the quality levels that they have achieved for their automobiles with the plant manager, he was very proud to disclose that the introduction of robotics led to significant increases in quality levels while reducing the level of vehicle manual inspection and rework of defects.

I later worked on a project that used advanced sensors to control a manufacturing operation. Although not strictly robotic in design, the use of these advanced sensors allowed the precision placement of components and adjustment by the machines to eliminate errors. This is something that conventional aseptic filling lines presently cannot do.

In several other advanced technology projects I have been involved with, companies have thrown away current playbooks for aseptic manufacturing and have used advanced robotic technology, new design paradigms and advanced sensors to enhance sterile drug and biologic manufacturing. If properly designed, these advanced systems greatly improve the sterility assurance of the products manufactured and can be a key driver in simplifying the contamination control strategies the company has used.

A special note about pharmacy compounding: There is no validity behind the excuse that it is too expensive to install small-volume aseptic filling systems in isolators that employ robotics. Hospitals are installing these advanced robotic systems, so why not mandate these systems for compounders? The compounding industry needs to reevaluate practices rooted in the past which rely on manual aseptic filling practices that still allow employees to contaminate their preparations and seriously injure patients or may even lead to patient death.

Finally, I would like to point out that the radiopharmaceutical and Positron Emission Tomography (PET drug) industry has not reported sterility recalls (1). And this industry does not use sterile gloves or gauntlets during its aseptic filling processes; they use remote, manual manipulators to handle radioactive drugs and use presterilized components to reduce the potential for microbial contamination.

Regulators Seek Improved Aseptic Practices

Both the U.S. Food and Drug Administration (FDA) and European Medicines Agency have been very concerned about aseptic processing and the need to have better-designed aseptic-filling practices. To compensate for the problems encountered with conventional filling systems, the regulators have required industry to make a significant effort to demonstrate that they have designed capable systems but, even after validation, these systems still present risks for the contamination of drug products.

The FDA's current good manufacturing practice requirements in 21 CFR 211.63 Equipment Design, Size, and Location state that “equipment used in the manufacture, processing, packing, or holding of a drug product shall be of appropriate design, adequate size, and suitably located to facilitate operations for its intended use and for its cleaning and maintenance” (2).

The FDA discussed the use of aseptic-processing isolation systems in its 2004 Guidance for Industry: Sterile Drug Products Produced by Aseptic Processing – Current Good Manufacturing Practice. The guidance states that a well-designed positive-pressure isolator offers tangible advantages that include fewer opportunities for microbial contamination. The guidance also cautions that users should be vigilant for sources of operational risks (3).

Section 2.1(i) of the European Union Annex 1 Manufacture of Sterile Medicinal Products states: “The use of appropriate technologies (e.g. Restricted Access Barriers Systems (RABS), isolators, robotic systems, rapid/alternative methods and continuous monitoring systems) should be considered to increase the protection of the product from potential extraneous sources of endotoxin/pyrogen, particulate and microbial contamination such as personnel, materials and the surrounding environment, and assist in the rapid detection of potential contaminants in the environment and the product” (4).

Annex 1, Section 8.127, reiterates the recommended use of closed systems, which can reduce the risk of microbial, particle and chemical contamination from the adjacent environment since closed systems are designed to reduce the need for manual manipulations and the associated risks.

Advanced Systems for Sterility Assurance

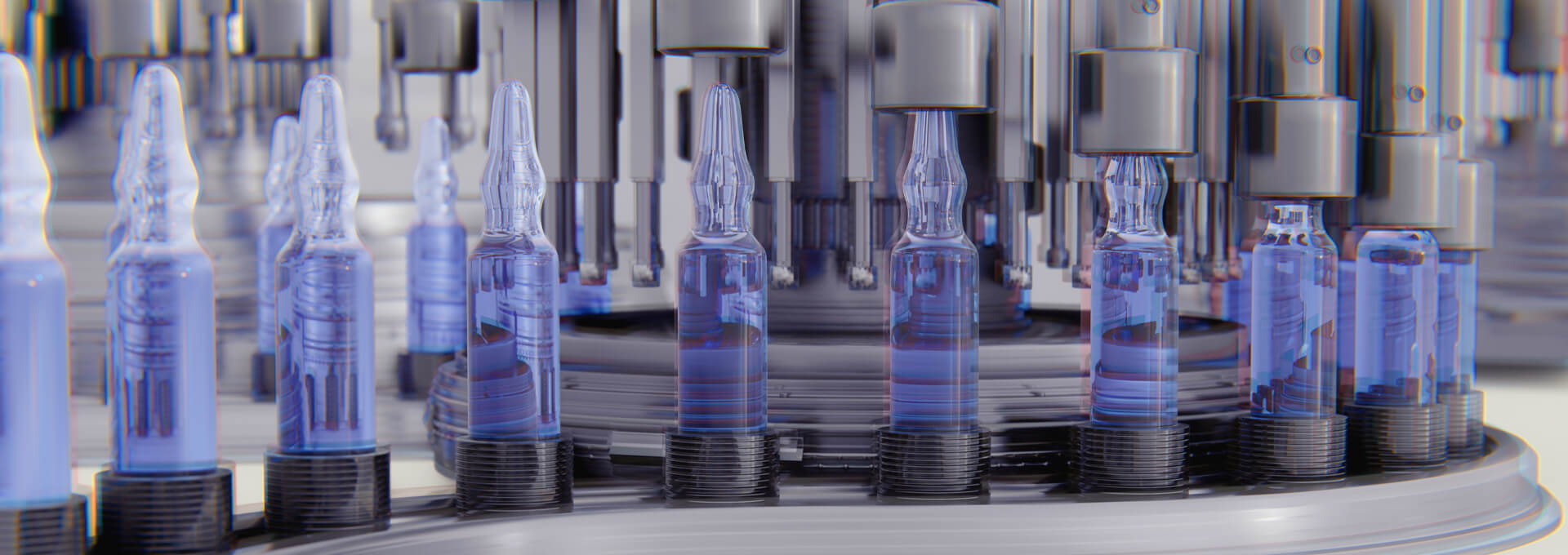

These regulations and guidances have stressed the need to ensure that system designs account for all sources of contamination. Currently, some companies have taken up this challenge and have introduced advanced robotic aseptic-processing systems that greatly improve the sterility assurance of their drug and biologic products. Is it time for the entire industry to reevaluate the equipment designs they are using for aseptic filling? I say yes, and I present the following for consideration regarding vials, syringes and IV bags, as well as the use of remote manipulators, advanced sensors and advanced robotic systems in pharmaceutical and biotech industries for their precision and enhancements in sterility assurance.

Remote Manipulators

The easiest change that manufacturers can make to existing RABS and isolator filling lines is to replace glove ports and gauntlet gloves with either manual or electronic remote manipulators. These can be used on existing RABS or isolator filling lines.

Manual remote manipulators are currently being used to manufacture radiopharmaceutical and PET drugs. These manipulators can be designed as master-slave manipulators or command-remote manipulators. Master-slave manipulators are ball manipulators that have limited degrees of freedom and limited area coverage. Command-remote manipulators have wrist joints and grippers that approximate the dexterity of the human hand and fingers. These manipulators (see Figure 1) can be designed for various weight limits for lifting and can be adapted to withstand repeated vaporized hydrogen peroxide and sporicide contact to prevent microbial and particulate contamination in an ISO-5 filling environment.

Electronically controlled manipulators are also available, and these types of manipulators can have very precise positioning and can have cameras installed to focus on the work being performed. They perform much like robotic arms, but they are not designed for repetitive tasks and are not programmed for specific tasks; they are controlled using hand actuators controlled by an employee. One example of this type of control can be seen in Figure 2.

With all remote manipulator systems, careful design for purpose and employee training is crucial for successful implementation. Employee training can take weeks to master but, once the training is completed, employees can perform tasks within an isolator as if they were working with their hands. In one demonstration, an employee was able to successfully thread a needle using a remote manipulator with a camera for close-up work. This link to research and development non-profit SRI demonstrates another example of how a computer-assisted remote manipulator would work. I would envision that line setup, cleaning and troubleshooting could easily be handled by such a manipulator.

Although the purchase of a remote manipulator system is initially more expensive than using glove ports and gauntlet gloves, the savings—purchase of glove-port testers not required, nor the time needed to test the gloves, no replacement of gauntlet gloves, reduction of downtime and reduction in glove leak investigations—can more than offset the increased costs. In addition, employees have found the use of remote manipulators less fatiguing, more ergonomic and easier to adapt to different employee heights and hand sizes.

In the long run, after a demonstrated success using remote manipulators, regulators could allow a reduction in the use of media fills and sterility testing or a further reduction in area classifications for rooms where isolator filling-lines are operated, since human interventions are eliminated as a sterility assurance risk.

In the next article, I will discuss the use of advanced sensors that can be installed on existing filling lines to detect equipment or component errors before they can cause a defective vial, syringe or IV bag to be produced.

The last article of the series will examine use of robotic systems for aseptic filling, where we are with their use and where we can go in the future.

Reference

- Food and Drug Administration. Recalls, Market Withdrawals, & Safety Alerts. FDA.gov recall database search conducted June 6, 2025; https://www.fda.gov/safety/recalls-market-withdrawals-safety-alerts.

- Food and Drug Administration. 21 CFR. 211.63 Equipment Design, Size, and Location; https://www.ecfr.gov/current/title-21/chapter-I/subchapter-C/part-211/subpart-D/section-211.63.

- Food and Drug Administration. Guidance for Industry: Sterile Drug Products Produced by Aseptic Processing — Current Good Manufacturing Practice. https://www.fda.gov/media/71026/download.

- European Commission. Annex 1: Manufacture of Sterile Medicinal Products, EudraLex – Volume 4 – EU Guidelines for Good Manufacturing Practice for Medicinal Products for Human and Veterinary Use. https://health.ec.europa.eu/document/download/e05af55b-38e9-42bf-8495-194bbf0b9262_en?filename=20220825_gmp-an1_en_0.pdf.