New Vial Technology Shows Promise for Manufacturing Productivity

Image courtesy of Corning.

Advances in pharmaceutical glass packaging offer advantages for both patients and manufacturers, but the potential of new innovations will not be reached without rigorous testing and line trials to confirm their benefits.

Valor® Glass, one example of such new technology, was introduced in 2017 as a tubular glass packaging solution with Type I hydrolytic performance that would substantially reduce particle contamination and prevent cracks. The idea was that its use would significantly increase throughput for pharmaceutical manufacturers (1–3). Considering that the U.S. FDA has called for improvement in glass manufacturing (4), Merck & Co. conducted a series of line trials to ensure the compatibility of Valor Glass vials with existing and new lines. The goal was to demonstrate that this innovative product could be introduced as a “drop in” solution and, potentially, deliver a higher quality glass solution. So, the company compared the performance of Valor Glass vials against the conventional borosilicate (Type I) vials currently used on their manufacturing lines.

To start the trials, a cross-functional team was established to provide the necessary expertise and experience to enable an objective assessment of the new technology. Strong sponsorship of the team ensured the availability of appropriate resources, funding and line time. This team developed a standard assessment approach that would be applied across multiple sites and products, so data gathered across various lines could be easily compared. Trials were designed to assess machinability performance, particulate generation, interventions, glass breakage and performance using visual inspection on filling and packaging lines.

The team, which included experts in glass manufacturing and handling, product impact/stability, manufacturing process, quality risk management and regulatory affairs, evaluated the performance of the vials. They set success criteria and maintained an objective viewpoint throughout the various line trials. Early engagement with regulatory agencies facilitated understanding of expectations and requirements needed for implementation (5).

Study Protocol Overview and Summary Results

For initial assessment, multiple engineering trials were run on a single line, demonstrating that the Valor Glass vials performed better when compared to historic conventional glass data. The new vials enabled a higher effective line speed (more vials filled and passing final inspection per unit of time), required fewer glass-related interventions and generated lower particulate contamination. These line trials tested 50,000 to more than 1,000,000 Valor vials. The result of the largest line trial is summarized in Table 1.

Table 1 Results of an Engineering Line Trial Comparing Valor Glass to Conventional Glass| Machinability Outcome | |||

|---|---|---|---|

|

Conventional Glass

|

Valor® Glass

|

Performance of Valor Glass Vials compared to Conventional Vials

|

|

| Effective Line Speed |

326 +/- 26 vpm

|

440 vpm

|

25% improvement |

| Interventions |

247

|

95

|

61% reduction |

| Particulates (at In-feed) |

50

|

4

|

92% reduction in nonviable particles at in-feed locations |

| Lubrication Events |

5

|

0

|

100% |

The results of the line trial confirmed the improved performance of Valor Glass vials compared to the conventional borosilicate vials currently in use.

Additional trials were conducted on different filling lines, including relatively new filling lines. The trials varied from hours to a single day of run time, with volumes ranging from 5,000 to 150,000 vials. Machinability was successful on each of these lines.

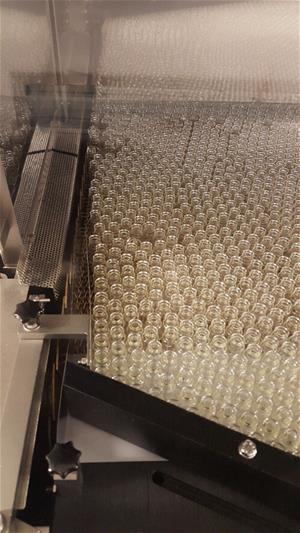

Efficiency on the Line

Valor Glass vials have a coating applied only to the outside of the vial, so there is no increased risk with respect to extractables and leachables. The external coating reduces the coefficient of friction of the vials, allowing them to process with less resistance on a filling line than conventional borosilicate vials. Consequently, the improved flow required adjustments to certain filling lines—lines where vials are moved “en masse” with accumulation points or that move glass via backpressure—to accommodate the smoother transfer of vials and the new flow pattern (Figure 1).

Figure 1 “En Masse” Movement of Glass on One of the First Trial Lines

Figure 1 “En Masse” Movement of Glass on One of the First Trial Lines

As shown in the observation of Lubrication Events in Table 1, the external coating on the vials eliminated the need for the application of lubricant on the line, which is used during the filling process for conventional borosilicate glass vials to improve glass flow and reduce glass events.

Crack Prevention

Valor Glass is inherently stronger and more damage-resistant than borosilicate vials. The product was designed with significantly greater mechanical strength and higher internal energy than conventional borosilicate glass vials, which also prevents the occurrence of cracks. While Valor Glass is inherently stronger, breakage is still possible. Unlike conventional vials that can incur difficult-to-detect cracks when severely damaged, Valor Glass is engineered to break rather than crack when severely damaged, and it breaks in a more controlled manner than conventional vials. That breakage signals a quality issue, such as improper line set-up, allowing operators to take corrective action immediately. Breakage events with Valor Glass vials, for example, can enable line operators to detect and correct such issues as:

- Misaligned transition that impacts the heel of the vial

- Improper capper set-up that causes the disk/rail to damage the neck of the vial

- Filling-needle strikes that occur at the top of the vial

The Valor Glass has not damaged equipment or exhibited cracks in any of the line testing performed to date.

Lyophilization with Valor Glass

The team also compared lyophilization between Valor Glass and current vials, following a multistage approach. The team established equivalence for critical dimensions between Valor Glass vials and conventional borosilicate vials. Laboratory-scale runs were conducted to assess respective freezing kinetics of both types of vials. Head-to-head comparisons were conducted using gravimetric analysis, and sublimation rate data were used to determine the relative heat transfer coefficients via mathematical modeling. The studies showed that Valor Glass had a slightly lower average heat transfer coefficient relative to conventional borosilicate glass. This finding was negligible, however, with no anticipated impact to the current primary drying times for the production lyophilization cycle.

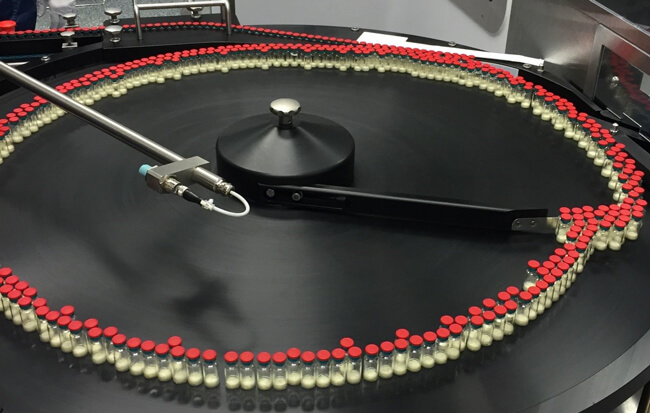

Following these comparability tests, commercial runs were conducted to assess the freezing profile, product moisture content, chamber pressure and overall lyophilization cake appearance (Figure 2). The results of the commercial-scale testing are summarized in Table 2.

Figure 2 Overall Appearance of Lyophilization Cakes in the Commercial-Scale Run

Figure 2 Overall Appearance of Lyophilization Cakes in the Commercial-Scale Run

| Lyophilization Comparability | Commercial-Scale Results |

|---|---|

| Freezing Profile and Chamber Pressure | Comparable |

| Moisture Mapping | Moisture results were within specification and comparable to historical performance |

| Lyophilization Cake Appearance | No change was observed |

Both laboratory- and commercial-scale testing demonstrated there was no need for adjustment in lyophilization-cycle parameters. No Valor Glass vials broke or cracked through the lyophilization process. The lyophilization performance of Valor Glass was deemed equivalent to that of conventional borosilicate glass vials for this specific application.

Thoughts on Control Strategy

As with most packaging changes, the engineering trials required minor equipment adjustments to enable smoother operations. The external coating of the Valor Glass vials imparts a significantly lower coefficient of friction than conventional glass, which can impact vial handling. This should be considered for machinability. The coating is durable but can be affected by extended durations at depyrogenation temperatures. The time should be monitored during extended line stoppages within the depyrogenation tunnel, and control measures should be set up to reduce the overall temperature exposure during prolonged stoppages to prevent coating degradation. Coating degradation results in a slight increase in coefficient of friction, but no loss in functional performance over the typical duration for normal processing at depyrogenation temperatures.

Valor Glass has an engineered binary response to damage, meaning that the vial is intact, or it breaks under extreme insult. This property could potentially enable enhanced quality assurance. When damaged in the uncoated flange region (specifically, the radii), Valor Glass may chip comparably to borosilicate containers; however, flange damage will not result in cracks. Breakage events with Valor Glass serve as a clear signal that suboptimal conditions may be present. While no equipment was damaged in any of the trials, precision in set-up and sensitivity to dimensional variation must be factored into engineering trials. The increased strength of the Valor Glass vial may also require equipment adjustments to ensure appropriate over-torque settings are in place in case of an event.

Any potential dimensional differences of the test vials compared to the current conventional borosilicate vials in use must also be evaluated and assessed. This is important to confirm both machinability and lyophilization equivalence.

Discussion

Valor Glass vials were specifically designed for use by pharmaceutical manufacturers. This new package solution is optimized to resist breakage and prevent cracks through ion exchange strengthening and a thermally stable exterior coating.

The external coating of Valor Glass imparts a low coefficient of friction, which should be considered for machinability. It also protects vials from damage or insults that can occur during processing, resulting in fewer particulates. The results of line trials for Valor Glass vials demonstrated more effective line speeds, fewer glass-related interventions required on the line and a significant reduction in particulate levels.

In addition, the Valor Glass vials showed no evidence of cracks in any of the trials. Instead, they exhibited a binary behavior in coated regions of the vial. The vials were either intact or broken; but cracks did not form in response to damage events. During machinability of Valor Glass vials, finish chips were noted, but only during atypical handling or when needle strikes resulted from misalignment. Valor Glass crack prevention is an important finding considering the challenges associated with cracked containers. These results may indicate an opportunity to decouple break events from concerns related to loss of sterility or purity of batch and could, ultimately, lead to a reevaluation of current regulatory notification expectations related to broken containers.

Conclusion

These trials demonstrated that Valor Glass has the potential to reduce particulate contamination, prevent cracks, and enhance throughput. Enabling the benefits of Valor Glass may require some optimization of manufacturing control strategies related to extended time in depyrogenation chambers and equipment setup, as discussed above. In addition, the unique attribute relating to crack prevention has the potential to reduce response activities related to broken containers.

References

- Schaut, R.A., et al., “A New Glass Option for Parenteral Packaging.” PDA JPST 68 (2014): 527–534.

- Timmons, C., et al. “Particulate Generation Mechanisms during Bulk Filling and Mitigation via New Glass Vial.” PDA JPST 71 (2017): 379–392.

- Schaut, R.A., et al. “Enhancing Patient Safety through the Use of a Pharmaceutical Glass Designed to Prevent Cracked Containers.” PDA JPST 71 (2017): 511–528.

- U.S. Food and Drug Administration. “Summary of Recent Findings Related to Glass Delamination.” May 9, 2018. www.fda.gov/drugs/pharmaceutical-quality-resources/summary-recent-findings-related-glass-delamination.

- “Merck and Pfizer Collaborate with Corning to Modernize Pharmaceutical Glass Packaging.” Press release. July 20, 2017. www.corning.com/worldwide/en/about-us/news-events/news-releases/2017/07/merck-and-pfizer-collaborate-with-corning-to-modernize-pharmaceutical-glass-packaging.html.

Dawn Watson is a Director of Engineering for Merck & Co. with 25 years of experience in the pharmaceutical industry. She works in the Sterile & Validation Center of Excellence managing a team that leads and executes global initiatives, provides expertise to resolve critical production issues, develops innovative solutions and ensures network alignment with industry and regulatory expectations.

Dawn Watson is a Director of Engineering for Merck & Co. with 25 years of experience in the pharmaceutical industry. She works in the Sterile & Validation Center of Excellence managing a team that leads and executes global initiatives, provides expertise to resolve critical production issues, develops innovative solutions and ensures network alignment with industry and regulatory expectations.